| Price | Member display |

Order number 00017 Processing customization No Item No. 00017

Model HPG Type Quick Connector

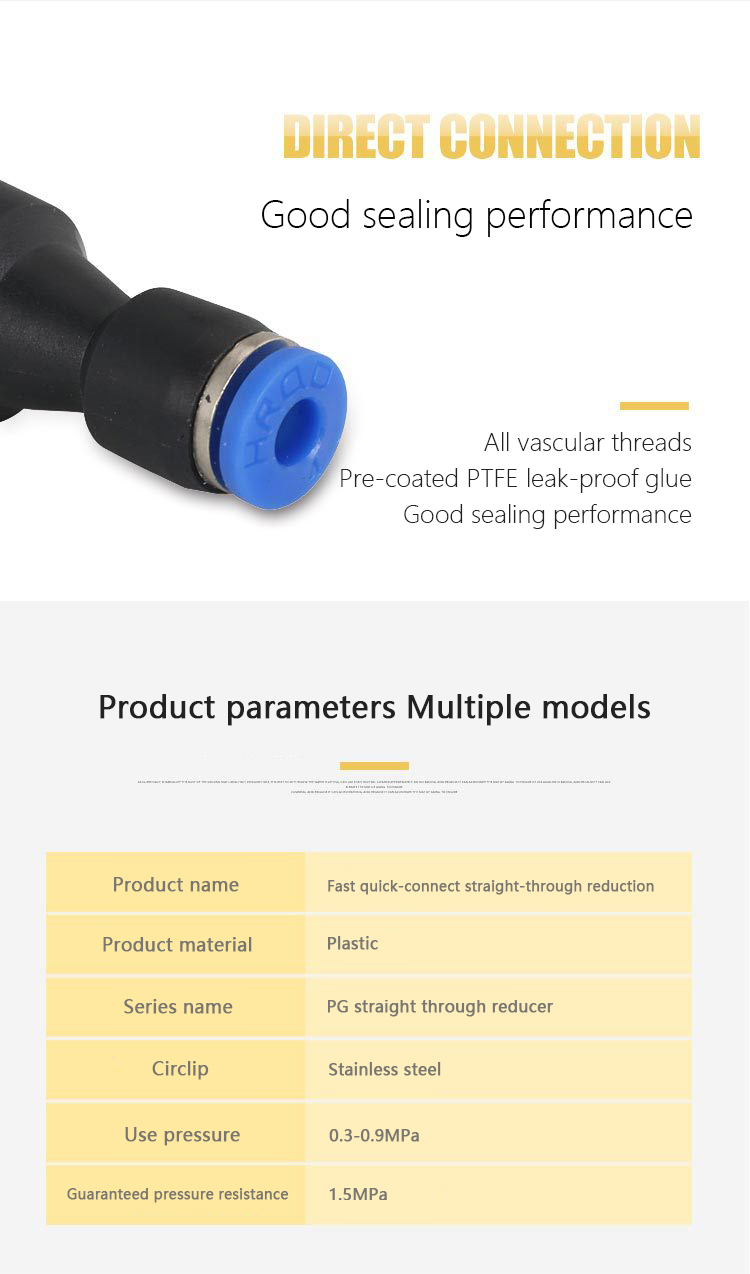

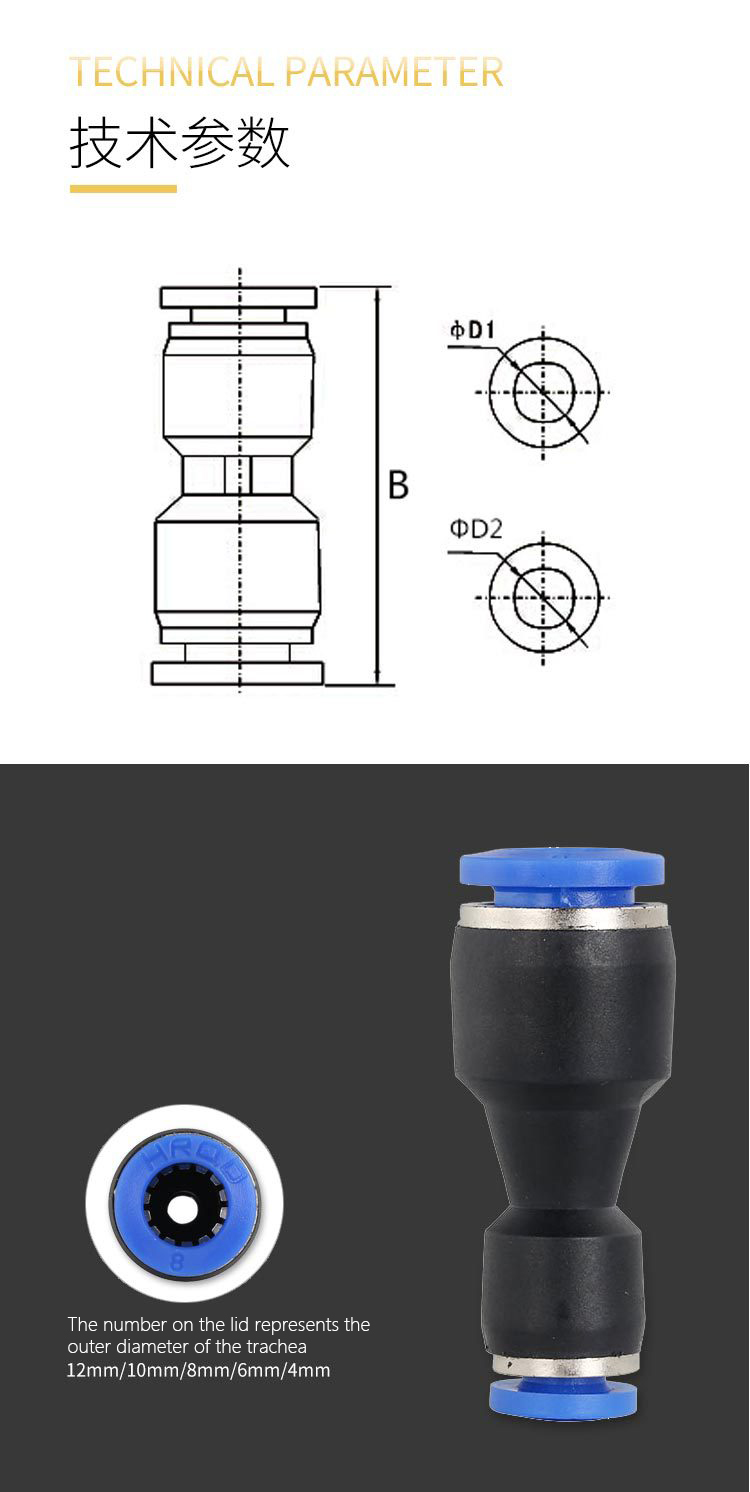

Material Plastic Scope PU tube Temperature resistance 0-70 (°C)

Withstand voltage 0-1 (MPa) Installation form Plug and play Connector diameter 6-4,8-6,10-8,12-10,8-4,10-6,12-8,16-12,14- 12,16-14 (mm)

A pipe joint is a valve that controls the flow of a fluid by changing the throttling section or the length of the throttling. The throttle valve and the check valve are connected in parallel to form a one-way throttle valve. The throttle valve and the one-way throttle valve are simple flow control valves. In the hydraulic system of the fixed pump, the throttle valve and the relief valve cooperate to form three throttling speed control systems, that is, the throttle throttle speed regulation System, return oil throttle control system and bypass throttle speed control system. The throttle valve has no negative flow feedback function and cannot compensate for the instability caused by the load change. It is generally only used in applications where the load does not change much or the speed stability is not high.

The performance requirements for the pipe joint are: · The flow adjustment range is large, and the flow-pressure difference changes smoothly;

·The amount of internal leakage is small. If there is an external leakage port, the amount of external leakage should be small;

·The adjustment torque is small and the action is sensitive.

Pipe joint features:

1. The structure is simple, easy to manufacture and maintain, and the cost is low.

2, the adjustment accuracy is not high, can not be used for adjustment.

3. The sealing surface is easy to be eroded and cannot be used as a cutting medium.

4. The sealing is poor.

Note on the use of connectors:

1. It is necessary to confirm that the cut surface of the pipe is vertical, there is no scratch on the outer circumference of the pipe and the pipe is not oval.

2. When inserting the pipe, it must be inserted into the bottom of the joint. If the pipe is not inserted, it may cause air leakage.

3. After the pipe is installed, pull the pipe to confirm that the pipe cannot be pulled out.

4. Please do not use it for purposes other than fluids.

5, do not exceed the maximum use pressure when using.

6. Do not use outside the temperature range to prevent deformation of the sealing material, which may lead to leakage.

7, do not artificially hit, bend, stretch, to prevent damage.

8. Do not use it in places such as metal powder or sand dust. If it is attached, it will cause poor work or leakage.

Precautions when disassembling: Use a suitable tool and use the outer hexagon of the fitting to remove the fitting. It is necessary to remove the sealing material that adheres to the opposite side of the pipe joint. Otherwise the adhered sealing material may enter the peripheral components, causing malfunction.