| Price | Member display |

Order number 00076 Processing customization No Item No. 00076

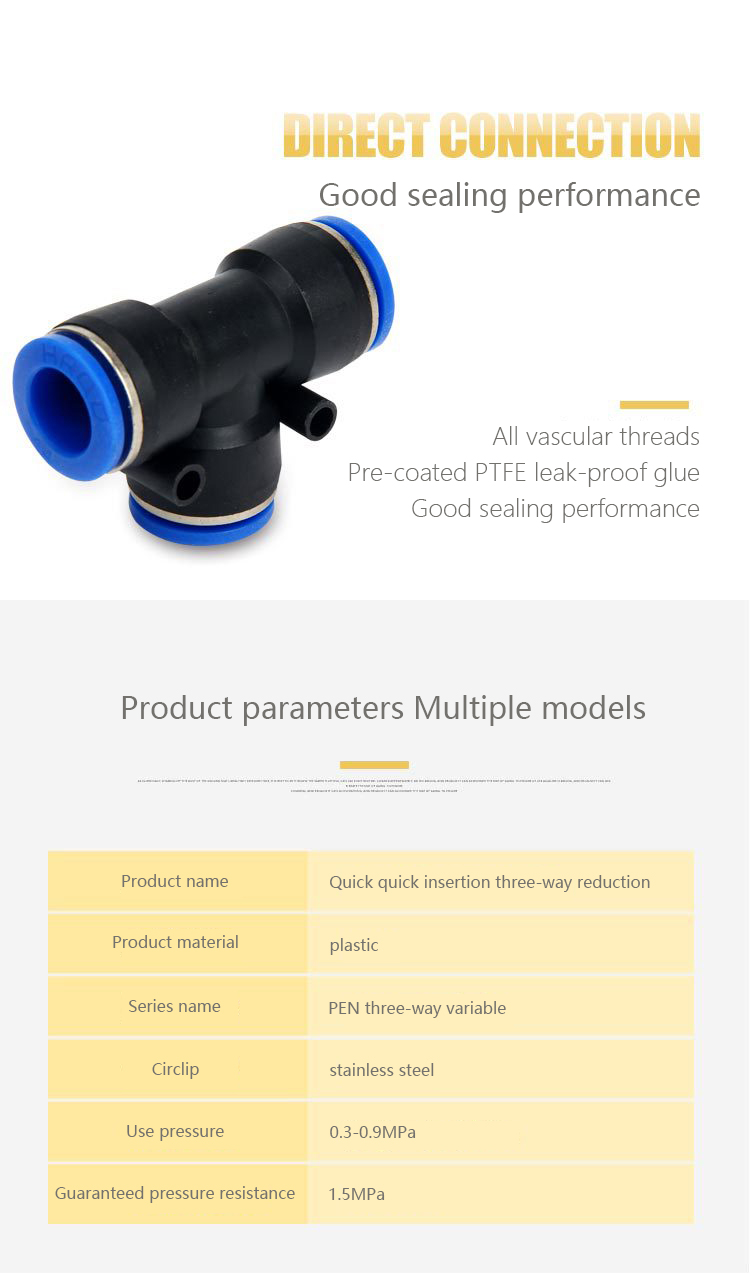

Model PEN Type Quick Connector

Material Plastic Scope PU tube Temperature resistance 0-70 (°C)

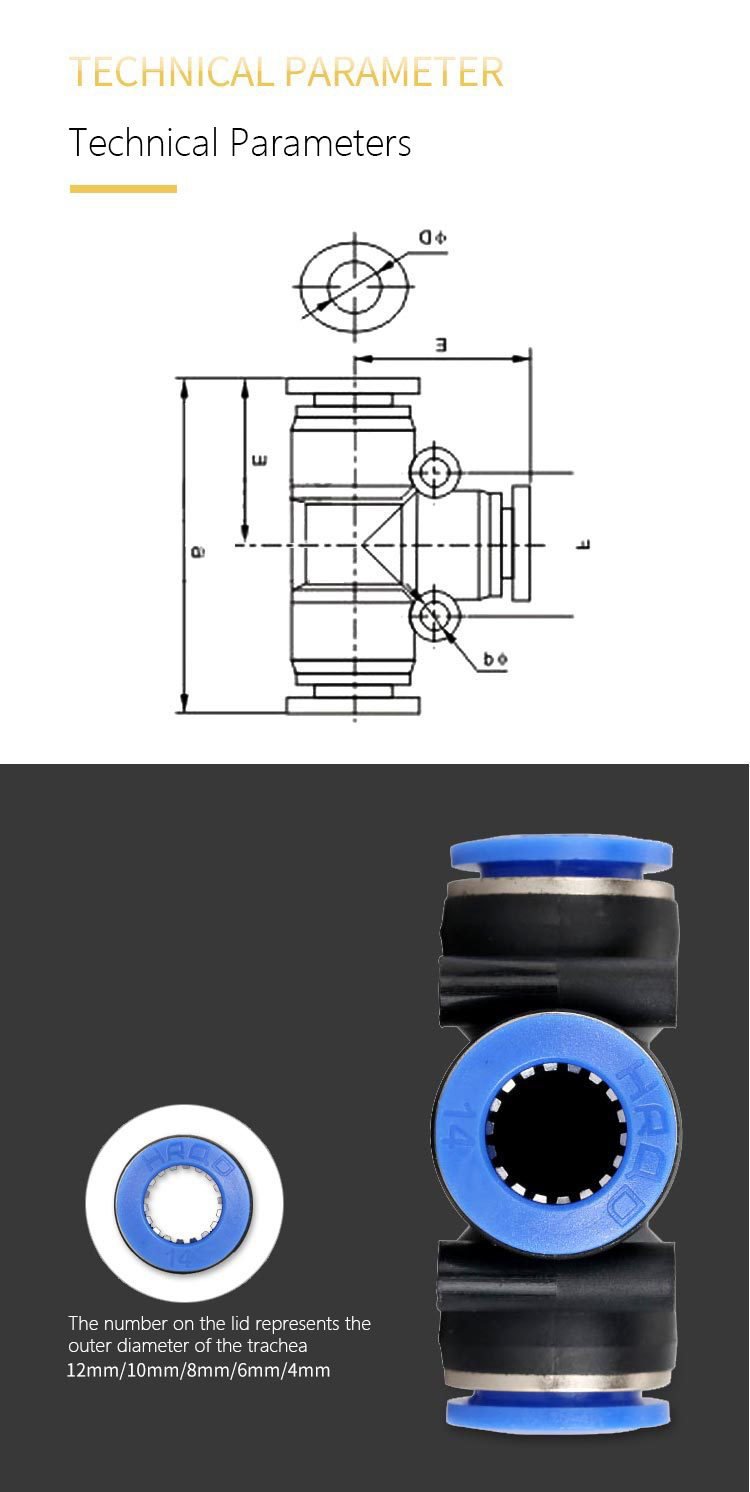

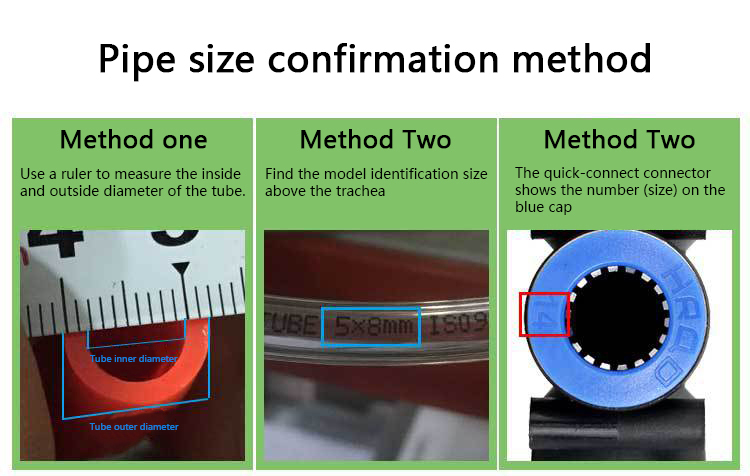

Withstand voltage 0-1 (MPa) Installation form Plug and play Connector diameter 6-4-6,16-12-16,12-10-12,8-6-8,8-4-8,10-8- 10,10-6-10,12-8-12,14-12-14, inverted three-way 6-8-6, inverted three-way 8-10-8, inverted three-way 10-12-10, inverted three-way 8-12-8 (mm)

Product Features:

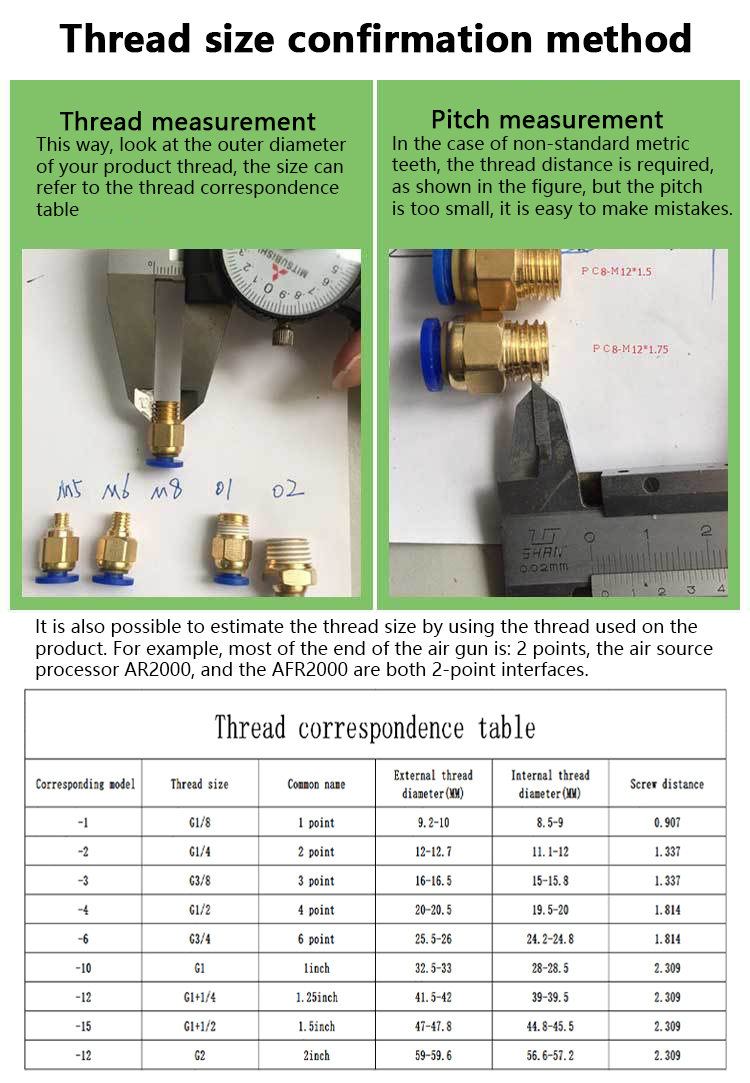

1. Simple and dexterous, with various forms to meet any needs.

2. Even after installation, the plastic pipe body can be arbitrarily turned.

3. The release ring adopts an elliptical design, which makes the disassembly more labor-saving and convenient.

4. All pipe threads are pre-coated with PTFE leak-proof glue for good sealing performance.

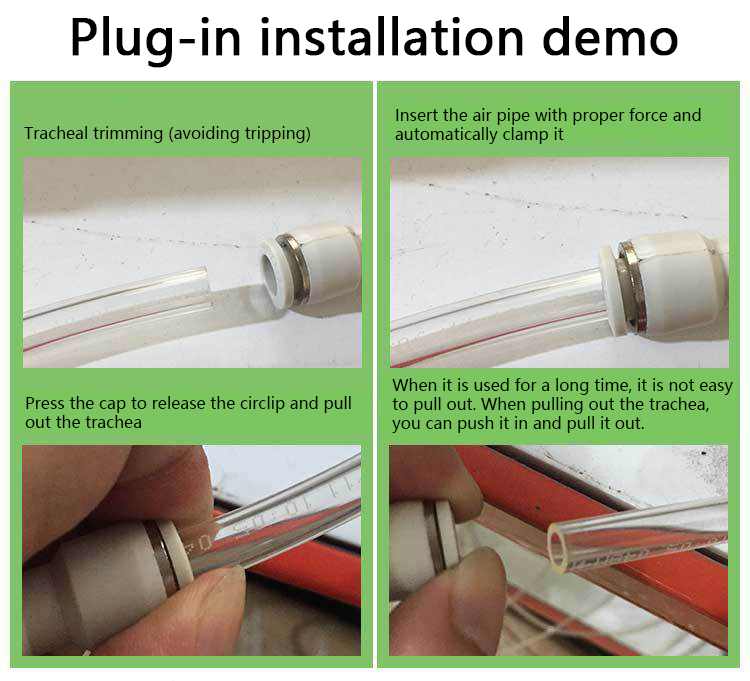

Takeover considerations

a. To confirm that the tracheal cross section is vertical, there is no scar on the outer circumference of the trachea.

b. To confirm that the trachea is inserted, be sure to insert it into the bottom of the connector. If it is not inserted into the bottom, it may cause air leakage.

c. After the trachea is inserted, pull it down and try to confirm that the trachea can not be pulled out.

Precautions when installing the connector body:

a. Use a suitable tool to mount the joint body with the outer hexagon of the pipe joint

b. When tightening the joint thread, it should be noted that the installation force should not be too large or too small. Excessively large may cause the thread to partially break and the seal to deform, resulting in leakage. Too small may cause loosening of the threaded portion.

C. After the joint is connected, the product with the same direction of contact can be adjusted within the tightening range. Note on the use of connectors:

1. It is necessary to confirm that the cut surface of the pipe is vertical, there is no scratch on the outer circumference of the pipe and the pipe is not oval.

2. When inserting the pipe, it must be inserted into the bottom of the joint. If the pipe is not inserted, it may cause air leakage.

3. After the pipe is installed, pull the pipe to confirm that the pipe cannot be pulled out.

4. Please do not use it for purposes other than fluids.

5, do not exceed the maximum use pressure when using.

6. Do not use outside the temperature range to prevent deformation of the sealing material, which may lead to leakage.

7, do not artificially hit, bend, stretch, to prevent damage.

8. Do not use it in places such as metal powder or sand dust. If it is attached, it will cause poor work or leakage.

Precautions when disassembling: Use a suitable tool and use the outer hexagon of the fitting to remove the fitting. It is necessary to remove the sealing material that adheres to the opposite side of the pipe joint. Otherwise the adhered sealing material may enter the peripheral components, causing malfunction.