| Price | Member display |

Order No. 00067 Processing Customization No Item No. 00067

Model HPNY Type Quick Connector

Material Plastic Scope PU tube Temperature resistance 0-70 (°C)

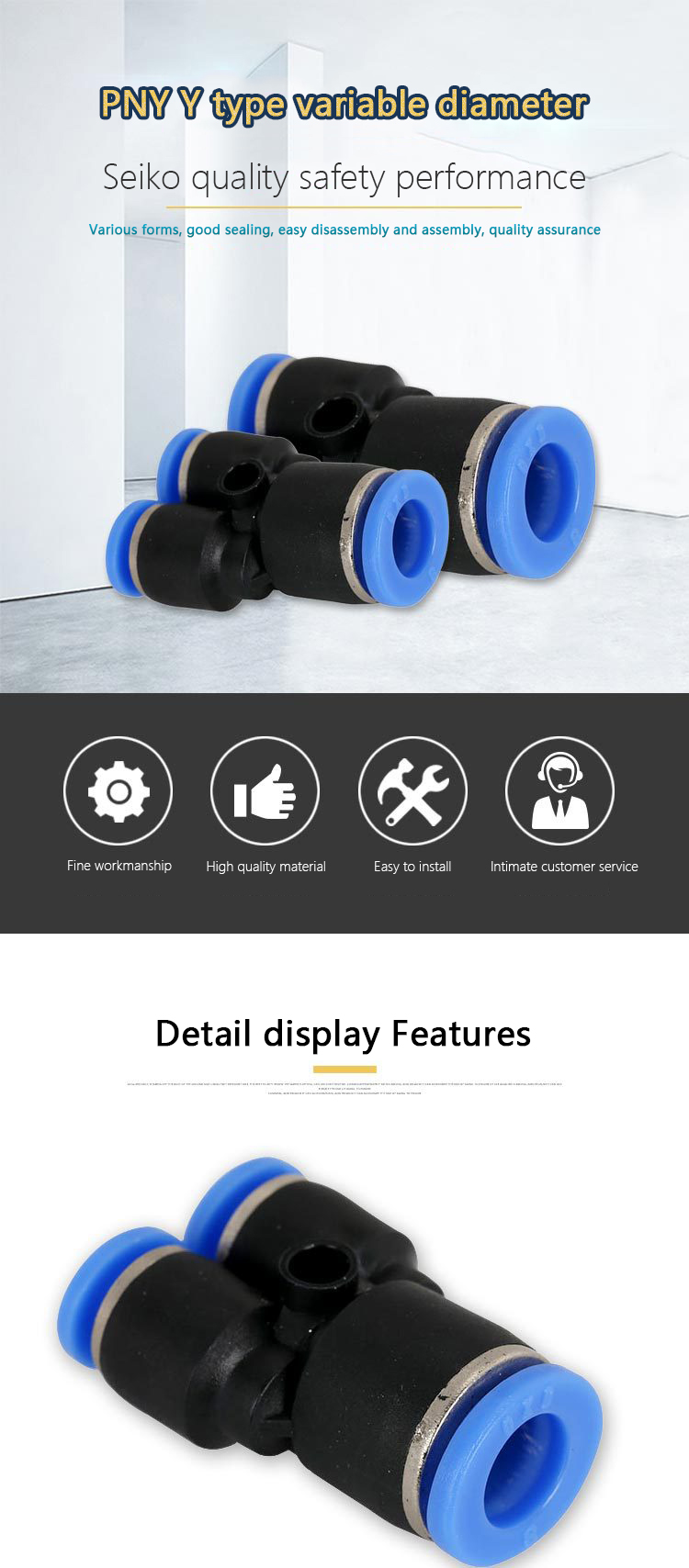

Withstand voltage 0-1 (MPa) Installation form Plug and play Receiver caliber 10-6-6,12-10-10,12-8-8,8-6-6,6-4-4,10-8- 8,16-12-12,14-12-12(mm)

The quick joint quick joint is a joint that can connect or disconnect the pipeline without tools. It has three structural forms: open and close at both ends, open at both ends, and single open and close.

1. Open and close at both ends: When not connected - When the ferrule of the parent body moves to the other end, the stainless steel beads automatically roll outward, and the daughter body is disconnected due to the force of the spring force of the common valve and the daughter body. The valves of the daughter and the parent are each closed, and the fluid flow is blocked instantaneously. When connecting - when the daughter body is inserted into the mother body, the ferrule returns to the original position under the action of the spring, the steel ball rolling locks the child body tightly connected, and the valve of the mother body and the child body pushes each other to open, fluid circulation, O type The ring completely blocks the leakage of the fluid.

2. Open ends are not connected - When the ferrule of the parent body is pushed to the other end, the steel ball automatically rolls outward, so the child body is removed; since there is no valve between the child body and the mother body, the fluid flows out. Connection - When the daughter is inserted into the parent, the ferrule is pushed to the previous position by the force of its spring, causing the ball to lock and the fluid to flow, with the O-ring in it to prevent liquid leakage.

3. When the single-channel open-close type is not connected - when the ferrule of the mother body is moved to the other end, the stainless steel beads automatically roll outward, and the child body is bounced off by the reaction force of the valve spring, and the valve can be automatically closed to block the fluid. flow. When connecting - when the child is inserted into the side of the parent body of the ferrule, the valve is opened to cause fluid to flow, the washer is pushed back to the original position by the force of the spring, the stainless steel beads are locked to ensure the connection of the child/parent, and the washer inside Can completely block the leakage of fluid.

Why use a quick connector?

1. Save time and effort: When the quick joint is used to disconnect and connect the oil circuit, the action is simple, saving time and manpower.

2. Fuel-saving: When the oil circuit is broken, the single valve on the quick connector can close the oil circuit, the oil will not flow out, and the oil pressure loss will be avoided.

3. Environmental protection: When the quick joint is broken and connected, the oil will not leak and protect the environment.

4, equipment and zero, easy to transport: large equipment or hydraulic tools that need to be portable, use quick joints to separate and transport, reach the destination and then assemble.

5. Economy: All the above advantages have created economic value for customers.

Quick connector features:

· Quick installation, simple and smart, saving space;

· Various types to meet the needs of any pneumatic pipe;

· Even after installation, the plastic pipe body can be arbitrarily turned;

·The release ring adopts elliptical design, which makes disassembly easier and more convenient;

·All taper pipe threads are pre-coated with PTFE leak-proof glue, and the sealing performance is good. Note on the use of joints:

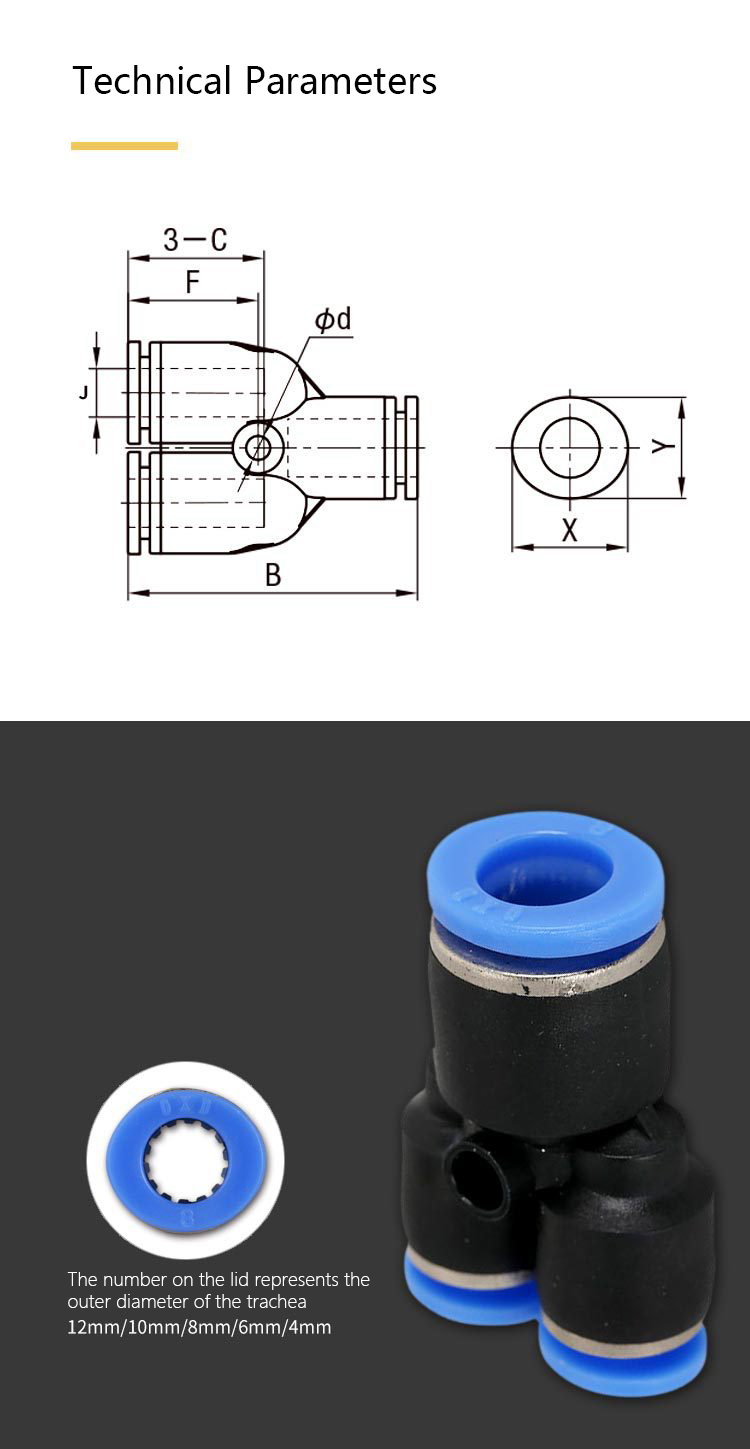

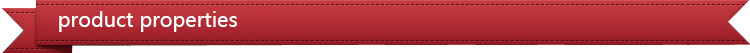

1. It is necessary to confirm that the cut surface of the pipe is vertical, there is no scratch on the outer circumference of the pipe and the pipe is not oval.

2. When inserting the pipe, it must be inserted into the bottom of the joint. If the pipe is not inserted, it may cause air leakage.

3. After the pipe is installed, pull the pipe to confirm that the pipe cannot be pulled out.

4. Please do not use it for purposes other than fluids.

5, do not exceed the maximum use pressure when using.

6. Do not use outside the temperature range to prevent deformation of the sealing material, which may lead to leakage.

7, do not artificially hit, bend, stretch, to prevent damage.

8. Do not use it in places such as metal powder or sand dust. If it is attached, it will cause poor work or leakage.

Precautions when disassembling: Use a suitable tool and use the outer hexagon of the fitting to remove the fitting. It is necessary to remove the sealing material that adheres to the opposite side of the pipe joint. Otherwise the adhered sealing material may enter the peripheral components, causing malfunction.